Impianti di innovazione sostenibile

Soluzioni per la trasformazione di rifiuti in energie e materie prime seconde.

Sistemi per l’evoluzione industriale applicando Intelligenza Artificiale, IIoT e Cyber Security.

Parlano di noi

Riciclo

Un’ampia gamma di singole macchine e impianti per la separazione e la trasformazione di scarti industriali e municipali.

La rivoluzione di Ecube nel settore delle cartiere!

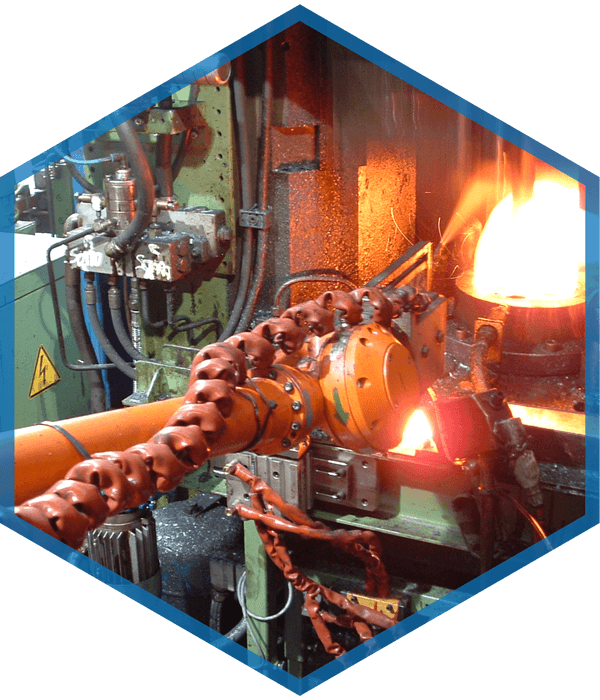

Robotica

Dalla manutenzione di un singolo robot, fino alla creazione di isole robotizzate in diversi settori industriali.

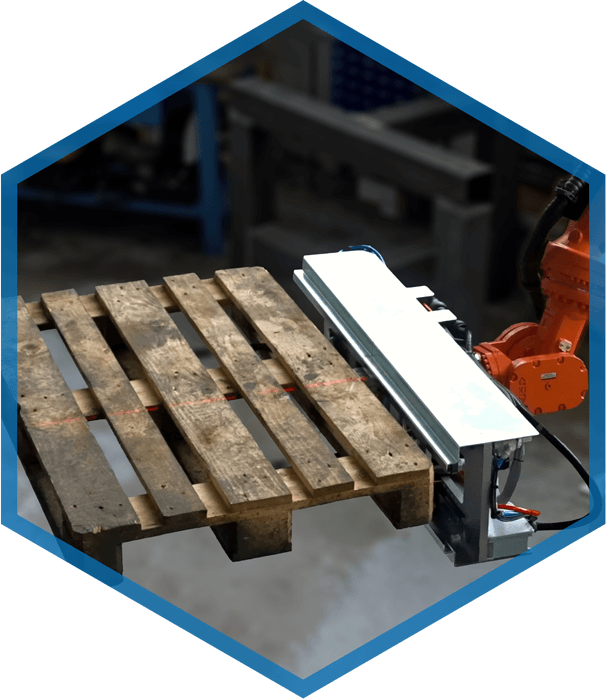

Visione

E-CyberScan sono i sistemi di visione che permettono il controllo qualità e riconoscimento di immagini in molteplici scenari.

Energia

Ecube propone soluzioni di trasformazione di sostanze organiche in energia termica ed elettrica mediante reattori di dissociazione molecolare pirolitici.

Industria 4.0

Soluzioni customizzate per la trasformazione dei processi industriali classici in processi digitalizzati e interconnessi.